Understanding OSHA and NEC Compliance in Electrical Work

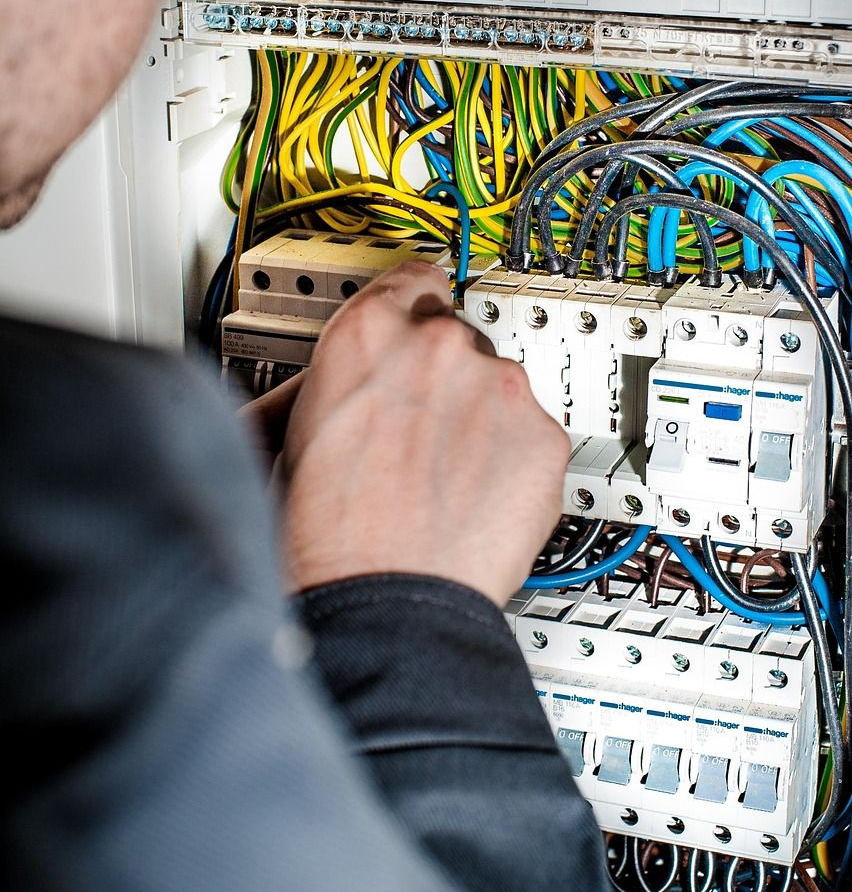

Commitment to Safety and Precision

Electrical work is among the most regulated trades in the construction industry, and for good reason. A single mistake in wiring, grounding, or installation can result in property damage, injury, or even loss of life. To prevent these outcomes, two governing standards set the foundation for safe electrical practice in the United States: the Occupational Safety and Health Administration (OSHA) and the National Electrical Code (NEC).

At ESD Electric, compliance with OSHA and NEC standards is not just a requirement but a responsibility. By following these regulations carefully, we ensure that every project meets the highest levels of safety, quality, and reliability for homes and businesses across Southern California.

The Role of OSHA in Electrical Safety

OSHA is a federal agency that establishes and enforces safety standards to protect workers on job sites. In the electrical field, OSHA’s primary objective is to prevent hazards such as electrocution, arc flashes, and electrical fires. The agency’s regulations cover a wide range of topics, including grounding methods, equipment use, lockout and tagout procedures, and personal protective equipment (PPE).

For electrical contractors, compliance begins long before work starts. OSHA requires employers to conduct safety training, maintain documentation, and ensure that employees understand the risks associated with electrical systems. This includes identifying live circuits, de-energizing equipment before servicing, and maintaining proper clearance around high-voltage areas.

At ESD Electric, our crews undergo ongoing OSHA-certified training. This ensures that every technician understands how to perform electrical work safely and in compliance with federal standards. We maintain a zero-tolerance policy for shortcuts and prioritize worker and client safety on every job site.

Understanding the National Electrical Code

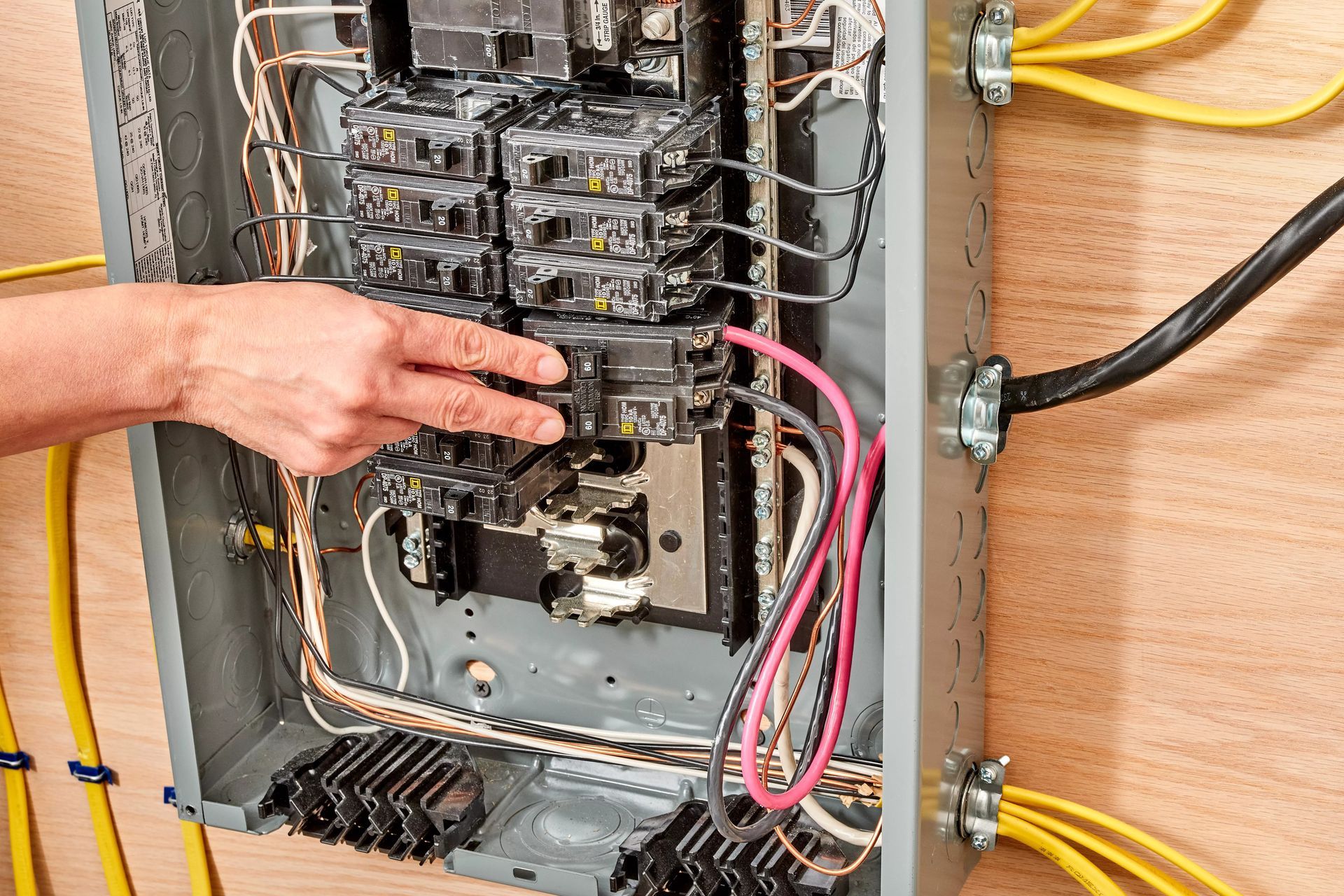

While OSHA focuses on worker safety, the National Electrical Code (NEC)—officially known as NFPA 70—sets the technical standards for safe electrical installation. Published by the National Fire Protection Association (NFPA), the NEC establishes uniform guidelines for wiring methods, grounding systems, overcurrent protection, and equipment placement.

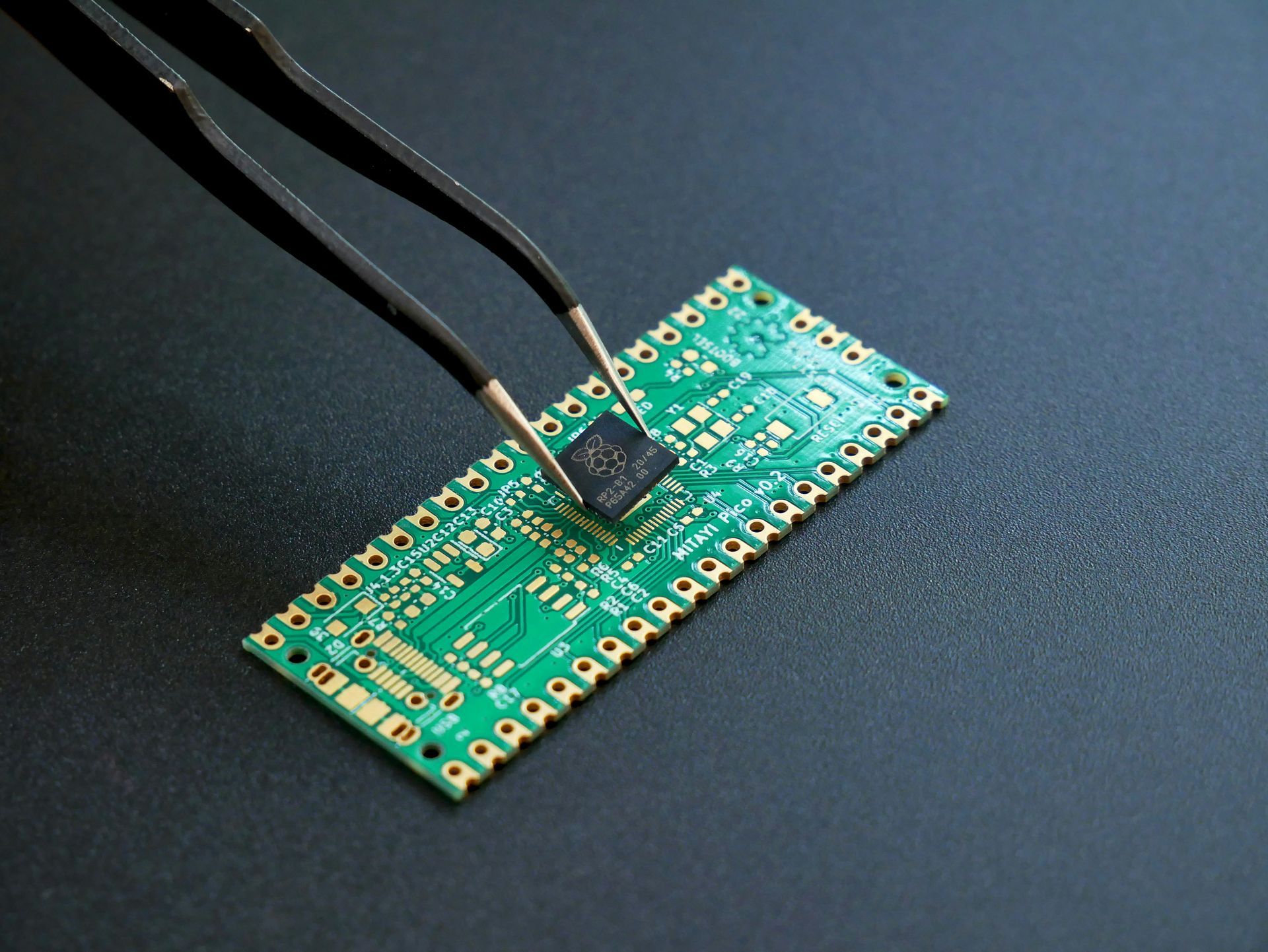

The NEC is updated every three years to reflect technological advancements and lessons learned from previous incidents. California has adopted the NEC as part of its state building code, which means all electrical work performed by ESD Electric must comply with its requirements.

Key NEC topics include:

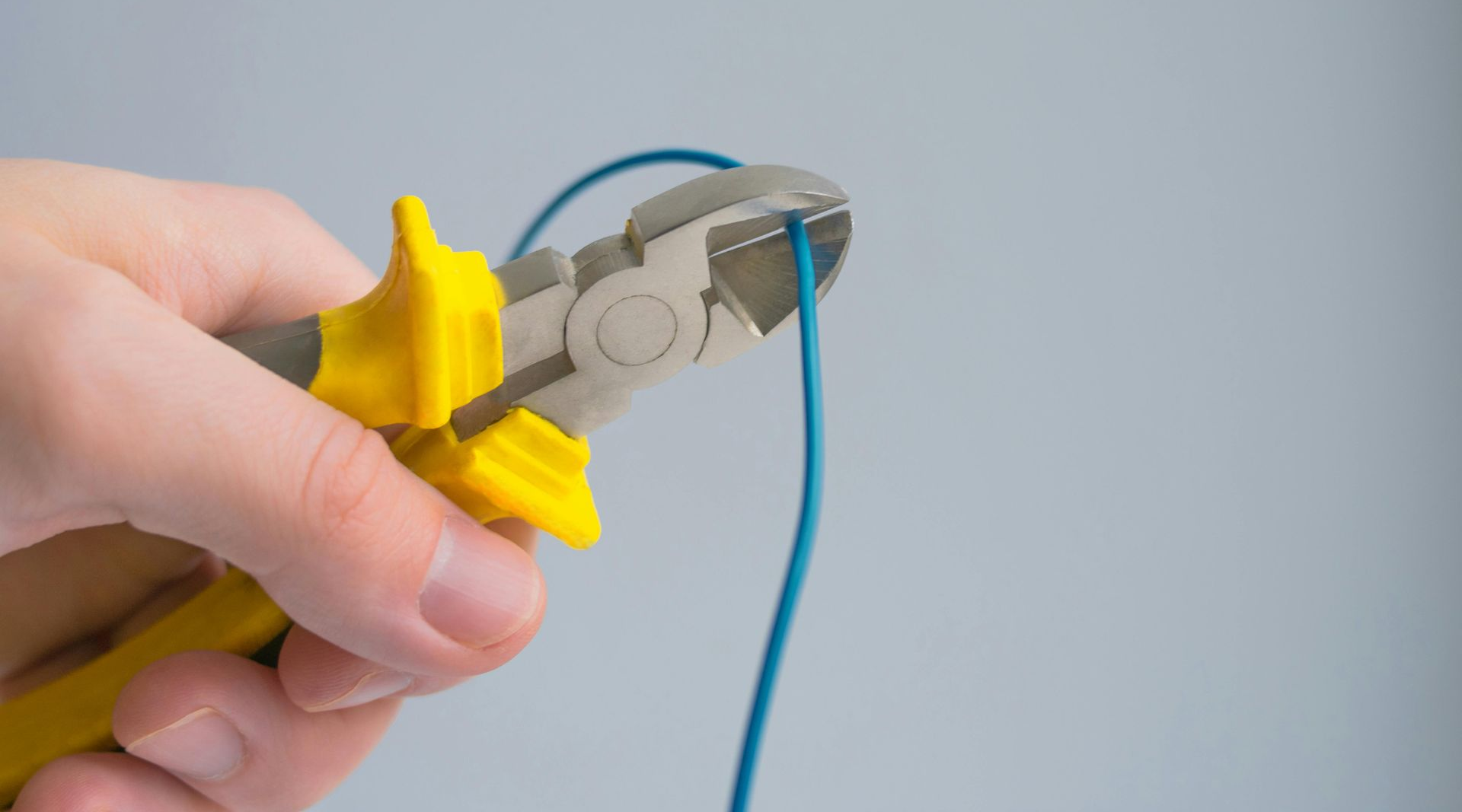

- Proper Wire Sizing: Ensuring that conductors can handle expected current loads without overheating.

- Ground Fault and Arc Fault Protection: Installing

GFCI and AFCI devices to prevent shocks and electrical fires.

- Conductor Insulation and Protection: Using appropriate materials for temperature, voltage, and environmental conditions.

- Equipment Grounding: Providing a continuous path for fault current to safely return to ground.

Every installation completed by ESD Electric is inspected for NEC compliance to guarantee long-term performance and safety.

The Importance of Dual Compliance

Both OSHA and NEC play distinct yet complementary roles in electrical safety. OSHA regulates how electrical work is performed, while the NEC regulates how electrical systems are designed and installed. Together, they provide a comprehensive safety framework.

Non-compliance with either standard can result in serious consequences. OSHA violations may lead to fines, work stoppages, or liability claims, while NEC violations can create life-threatening hazards such as electrical fires or equipment failure. Adhering to both is essential not only for regulatory approval but also for protecting workers, clients, and property.

ESD Electric’s Commitment to Safety and Compliance

At ESD Electric, every project is executed with full attention to OSHA and NEC standards. From residential remodels to large commercial installations, we begin with detailed planning, risk assessment, and system design based on the latest codes. Our technicians use high-quality materials and perform thorough inspections to ensure every circuit, outlet, and panel meets or exceeds industry requirements.

In addition to compliance, ESD Electric aligns its practices with ESG principles and LEED certification standards, supporting sustainability through energy-efficient designs and environmentally responsible installations. We believe that true professionalism in electrical work includes safety, reliability, and respect for the environment.

Final Thoughts

Electrical safety is never optional. By adhering to OSHA regulations and the National Electrical Code, contractors create safer environments for workers, clients, and communities. At ESD Electric, compliance is not a formality—it is the foundation of our work. Our dedication to precision, education, and accountability ensures that every project we complete stands as a model of quality and integrity.

Whether you are building a new home, upgrading a commercial facility, or ensuring compliance for an existing electrical system, ESD Electric delivers dependable solutions grounded in safety and excellence.