How Regular Electrical Maintenance Reduces Downtime in Commercial Facilities

Smart Maintenance, Stronger Systems

In commercial environments, electrical reliability is essential to productivity, safety, and cost control. Power interruptions, equipment malfunctions, and safety violations can halt operations and result in expensive downtime. The most effective way to avoid these issues is through consistent, professional electrical maintenance. At ESD Electric, we help businesses across Southern California maintain safe, energy-efficient, and compliant electrical systems that protect workers, minimize waste, and extend the life of vital infrastructure.

Why Maintenance Matters

Every electrical system experiences gradual wear over time. Heat cycles, vibration, moisture, and dust all contribute to the slow degradation of wires, terminals, and insulation. Left unchecked, these small issues accumulate until they cause serious failures such as breaker trips, power surges, or even fires.

Routine electrical maintenance identifies and corrects problems before they lead to operational disruptions. A single failed component can cause downtime that affects hundreds of employees or thousands of dollars in production. Regular inspection and servicing prevent these risks while maintaining compliance with

OSHA regulations and

California’s Title 24 energy standards.

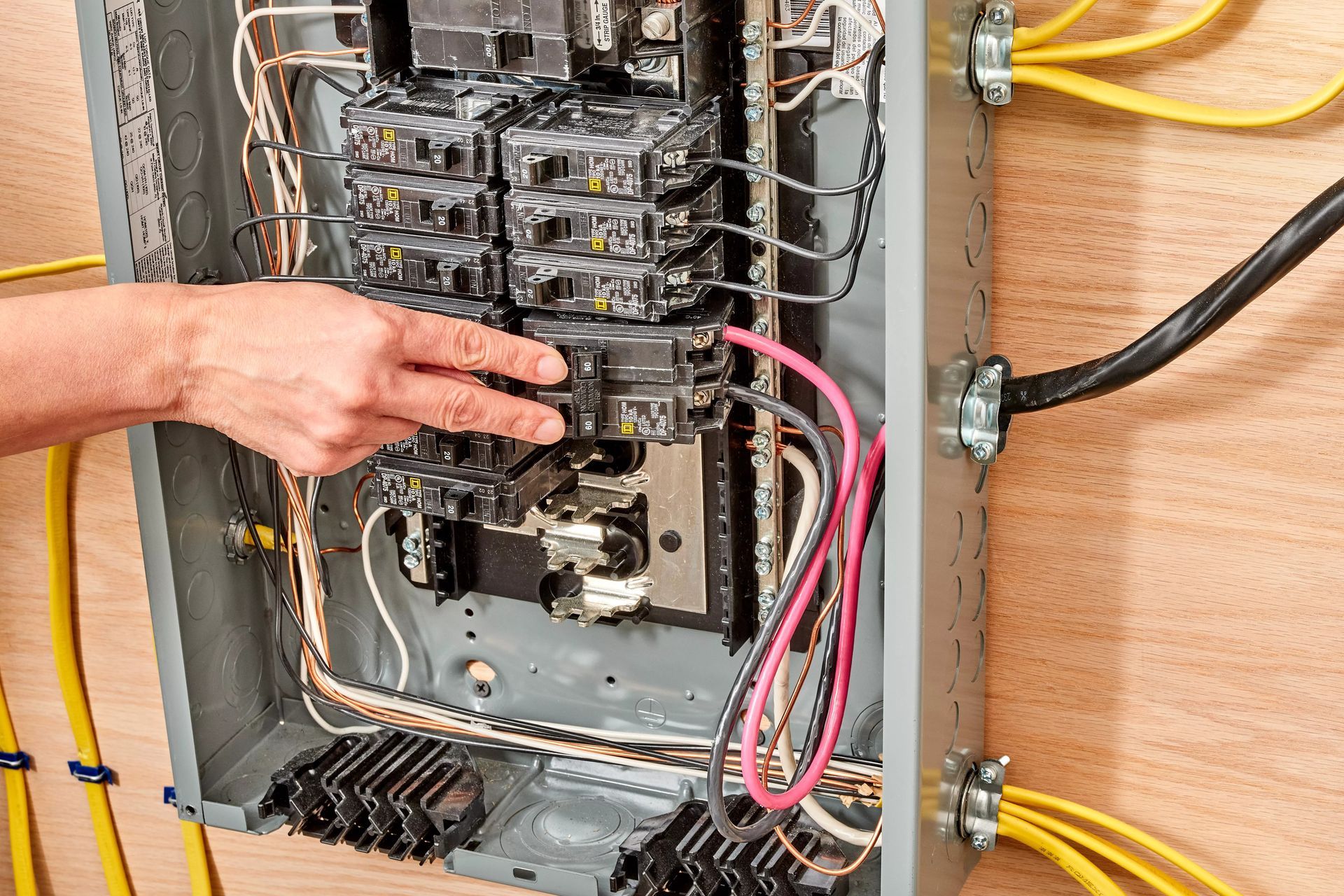

Comprehensive Inspection and Testing

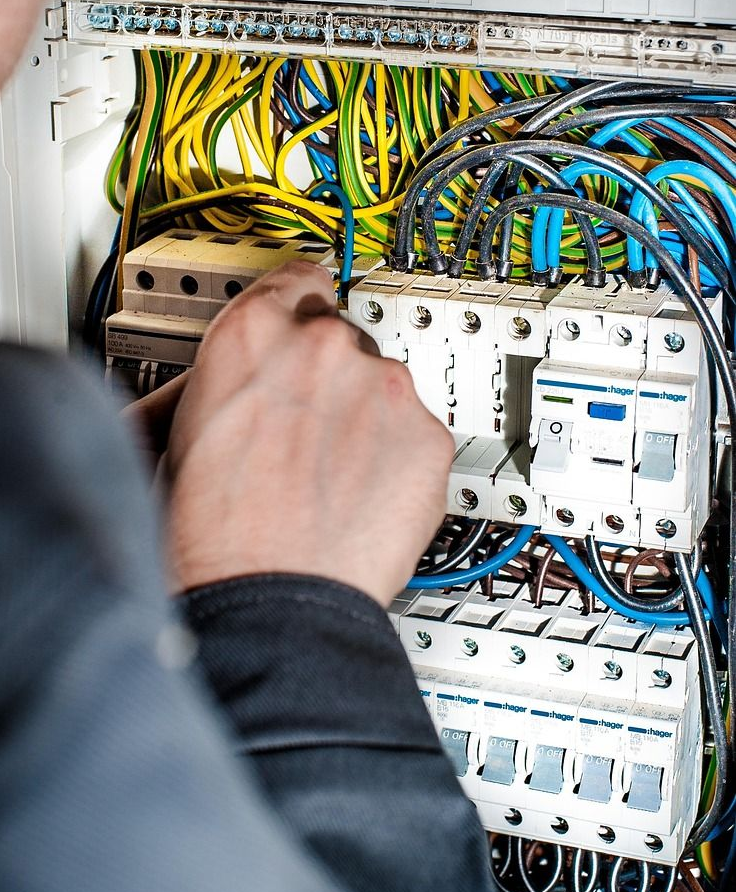

Preventive maintenance begins with a detailed inspection of electrical panels, conduits, breakers, and transformers. ESD Electric uses advanced diagnostic tools such as infrared thermography to detect overheating components or hidden faults that are invisible to the naked eye. Identifying these issues early allows our electricians to take corrective action before small anomalies become costly breakdowns.

We also perform voltage, amperage, and grounding tests to confirm that all circuits are operating safely within design parameters. Documenting this data provides a valuable baseline for facility managers, allowing them to track performance trends over time and support reporting for ESG and LEED compliance.

Cleaning and Component Upkeep

Dust and debris are common culprits behind electrical malfunctions. Even a thin layer of dust inside a switchgear or control panel can create conductive paths that lead to arcing, overheating, and corrosion. Our technicians follow OSHA-approved safety procedures to clean and restore sensitive components, improving conductivity and extending system longevity.

Proper cleaning also reduces the load on cooling systems. When electrical panels remain free of dust and heat buildup, they operate more efficiently and require less power to maintain safe operating temperatures. This small improvement in system efficiency can translate into substantial energy savings over time.

Energy Efficiency and Compliance

A well-maintained electrical system not only prevents downtime but also reduces operating costs. Balanced loads, optimized circuits, and calibrated breakers ensure that energy flows evenly and efficiently throughout the facility. This balance minimizes voltage drops, prevents power waste, and improves overall energy performance—a key metric for businesses pursuing LEED certification or ESG alignment.

Regular maintenance also ensures ongoing compliance with OSHA and California energy regulations. Our inspections verify that labeling, grounding, and emergency shutoffs meet or exceed code requirements. This proactive approach minimizes liability exposure during official audits or insurance inspections and reinforces a company’s commitment to workplace safety.

Tailored Programs for Long-Term Reliability

No two facilities operate under the same conditions. That is why ESD Electric customizes every maintenance program to match the unique needs and schedules of our clients. We coordinate inspections and repairs during off-hours or planned shutdowns to minimize disruption. Following each visit, our team provides detailed reports outlining all findings, corrections, and recommendations for continued improvement.

These reports serve not only as maintenance records but also as proof of compliance, supporting internal audits and long-term asset management strategies. With this documentation, facility managers can plan capital improvements more effectively and budget for future upgrades with confidence.

Powering Efficiency Through Professional Care

At ESD Electric, we believe that electrical maintenance is an investment in productivity, safety, and sustainability. Our experienced electricians combine technical precision with a deep understanding of OSHA compliance, energy efficiency, and modern ESG standards. By keeping systems clean, balanced, and fully functional, we help businesses operate without interruption while lowering energy costs and environmental impact.

If your facility depends on consistent electrical performance, proactive maintenance is the smartest way to safeguard your investment. Contact ESD Electric today to schedule a consultation and discover how our professional maintenance programs can keep your operations running smoothly and efficiently year-round.